Introduction of Slip-on Flange Forging Methods

This technical article introduces us about some main forging methods of slip-on flanges according to the movement of the forging die.

How to Correctly Select Flange

This technical article introduces us in details about that some main ways and methods that we can choose and select flanges correctly.

Thin-walled SS Tube Is Increasingly Widely Used

With the implementation of reform and opening policy and the development of economy, thin-walled stainless steel tubes are more and more popular.

Venezuela's Manufacturer Will Set Up Factories in Cuba

The company is evaluating the factory of the pipeline construction project, thus it is going to set up factories in Cuba.

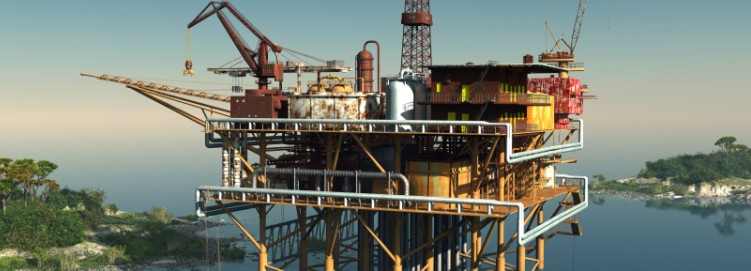

NDRC: Increase Gas Imports and Oil Reserves in Winter

The National Development and Reform Commission decided to increase gas imports and oil reserves in this winter in the meeting held on November 13.

How Are Large Flanges Operated and Processed

4. Flanges can be gained higher machining precision if being adopted multi-functional machine tool on site. Machine tool can be processed precisely not only by milling but also by grinding, honing, polishing and other finishing technology.